- The Samsung display unveils a MOD MOD wall screen

- Key technology change is a 60% reduction in glasses on OLED screens

- It is very similar to the micro-LED product of Samsung, but OLED

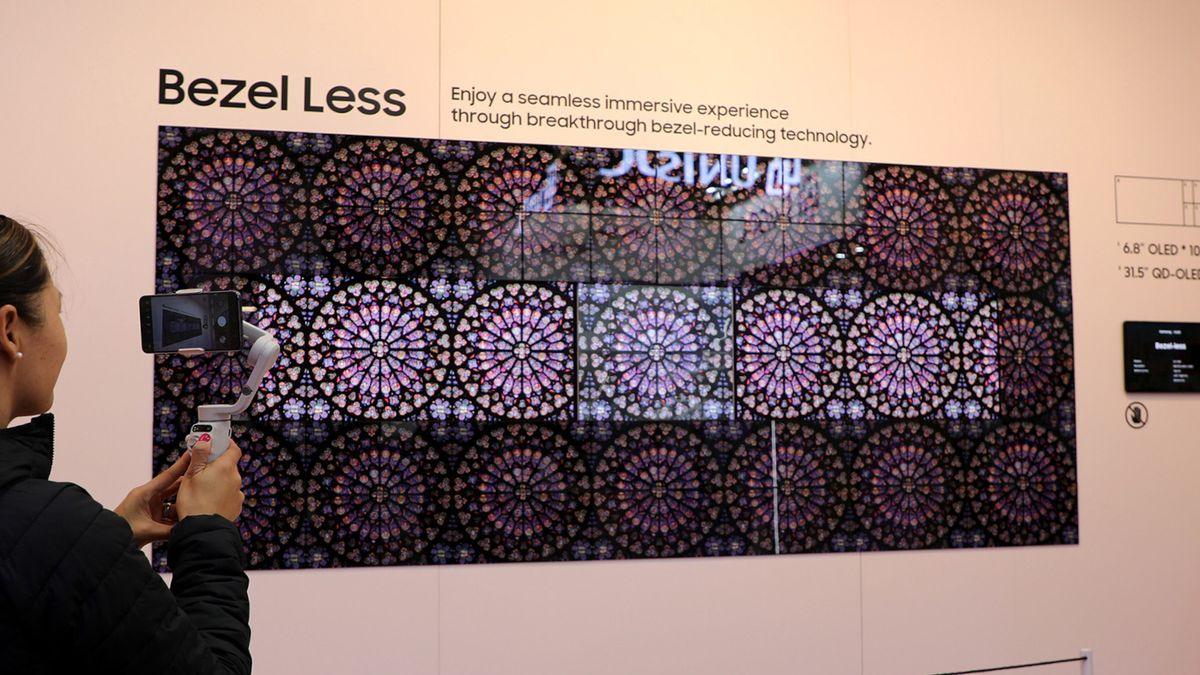

The Samsung display has unveiled a new modular OLED screen concept, in which a screen of a particular size or shape can be built using a series of smaller OLED displays tiled together (via the TOM guide).

If the idea seems familiar, it is because it is a very similar idea on the micro -LED screen of Samsung – but it is the first time that we have seen the idea applied to Oled.

The change in key technology that has made possible is that Samsung says that it can reduce the necessary glasses by 40% on the OLED and QD panels, the panels, bringing them to 0.6 mm. NOW, each The panel has this telescope, so in fact, there is a 1.2 mm border between the screens, which will be enough of a black line to be noticeable, which is probably part of the reason why it remains a concept for the moment.

But suppose that Samsung can continue to improve technology and can make the telescope even smaller, in which case I think it makes this technology extremely interesting to create Giant projector OLED TV screens. But I am not necessarily interested in the illustrated square modular concept above – the same technology could be applied in a similar way.

I immediately started to think about how the prices of the best OLED televisions are increasing exponentially as sets increase, due to the particular quirks in OLED production, and how the combination of smaller screens could make them much more profitable.

Four 55 -inch televisions in a trench

To illustrate what I mean, I will use LG OLED TVs rather than that of Samsung, due to the sizes involved. The LG G5 flagship range (the company) includes a 97 -inch model, and it costs $ 24,999 / 24,999 £.

It is literally 10 times the price of the 55 -inch LG G5 model, which costs $ 2,499 / £ 2,399. And the 97 -inch model actually has a lower panel – there are a few generations behind, and will be far from being as shiny as the main RGB panel in the RGB tandem of the 55 -inch model.

The reason is that it is incredibly difficult to make OLED TV panels on a large scale. OLED screens are produced on huge leaves called “mother glass” which are then reduced to smaller sizes; Thus, you can produce almost four times more 55 inch screens per glass sheet that you can 97 -inch screens.

But also, OLED production still has performance problems, which means that many screens are imperfect, and this waste is taken into account the cost of screens. If you produce a plot Panels by mother glass (if you make phone screens for example), then waste does not matter too much – losing a panel is only wasted with a tiny amount of material and your time.

But if you make 97 -inch panels and there is a problem, you have lost a huge amount of equipment and time, and these costs are taken into account in the price of good panels, effectively.

Thus, the modular concept is immediately interesting because it solves this problem: combining smaller screens in a larger display and massively reduce the problem of waste.

So, what I think is the following: if the glasses can be reduced more, could we have an 110-inch OLED TV in the future which is in fact four 55-inch televisions combined in a unit? It is even greater than the 97 -inch model, and yet could cost (relatively) only $ 10,000, based on the cost of four 55 -inch LG G5 televisions.

And I used LG as my example because of the easy size comparison with existing televisions, but this new technology comes from Samsung to potentially use in its QD OLED televisions – and it’s even better, Because these panels are not going to be more than 77 inches now, which would allow it to offer a giant OLED for the first time.

It’s not as simple as all this, of course. The combination of four OLED 4K panels means that we are talking about an 8K TV, although Samsung has a lot of experience with 8K treatment.

And in addition, many purists – that is to say the people most likely to want this television – would reject any sign of a seam between the panels, so unless the glasses can be completely deleted, I probably speak of something of a pipe dream.

But it would not be the first time that a secret double -screen secret configuration has been used to make more realistic cutting -edge technology – the first 5K display on an IMAC Apple was literally two 1280 x 1440 screens powered by a personalized display processor to treat them as a single unit, seamless in the middle.

Obviously, the construction of a TV from small squares also solves the screen problem, but there is a simplicity to repair four 4K TVs together which solves problems such as dealing with non -standard resolution.

I do not think that we will see an 110 -inch OLED built in this way in competition with the best televisions so early – but if this technology reducing the telescope continues to improve, this could make the home screen of your dreams possible, in particular with the micro -LED which does not seem to become affordable in the near future.