While the battle for electric vehicles with the longest range may well have been shifting, a new arms race began in its place – and it is a question of loading speeds.

In China, some of the most recognizable car and technological brands in the world are lasting to see who can force electrons in a battery at the most impressive rates.

After all, if the said industry giants can systematically provide charging times in accordance with the supply of an internal combustion engine vehicle, anxiety of the distribution area is essentially banished in history books and additional weight, the financial resources and penalties of larger battery packets are no longer a problem.

But while the so-called Mégawatt ultra-fast charge (everything that is greater than 1,000 kW) has languages that stir with pure and physics of all this, some believe that the road to two-minute fillings will not be so fluid.

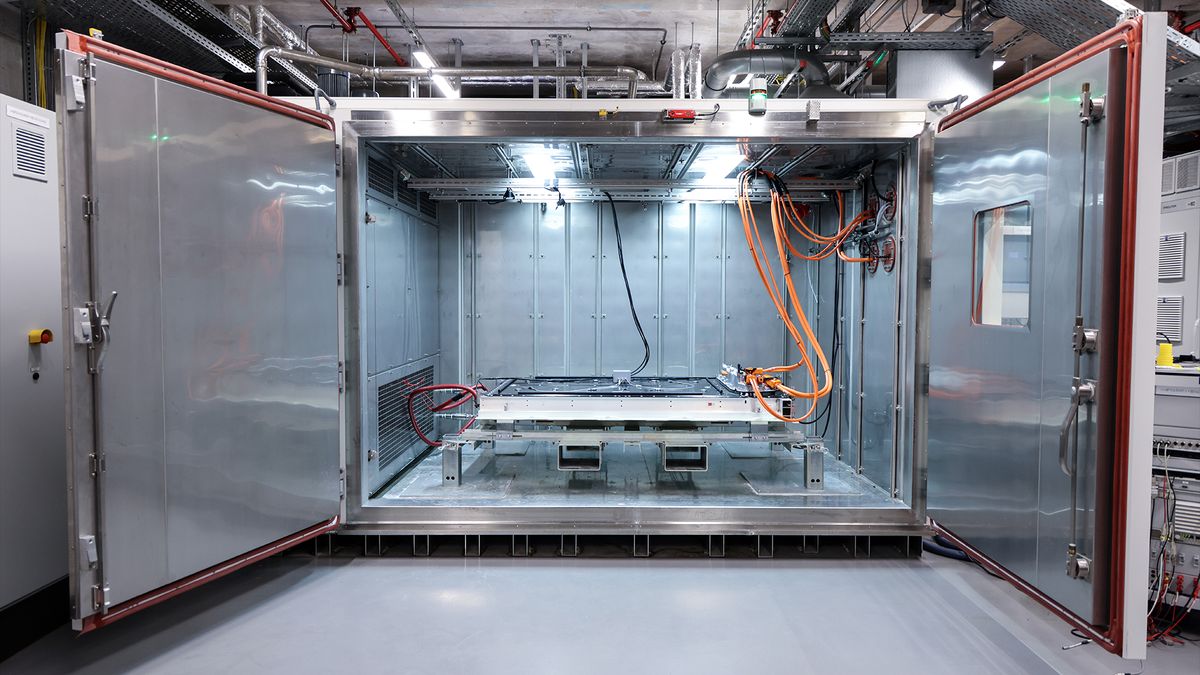

During a recent technology workshop of the battery of electric vehicles at Porsche R&D in Weissach, the company spoke frankly and finally its own road to electrification, marking the enormous jumps it has done with the current Taycan generation and what the future has in store for us.

Asked about the current trend of Megawatt, the development of Porsche in high-voltage lithium-ion batteries, Carlos Alberto Cordova Tineo, said that even if it was impressive, he does not think that it is the future for everyone.

“It is relatively easy to demonstrate this type of ultra-fast charge level on a test bench, but making it work in the real world is a much more difficult task. There are so many factors to consider when loading at these rates,” he told me.

One of the key problems of Porsche is the longevity of the battery, because the company wants its cars to offer the same type of driving sensations in 20 to 30 years as when they deploy the production chain.

Aside from the current residual values of Porsche electric vehicles, company cars are generally extremely sought after, many in progress to become objects to collect.

“All lithium-ion batteries undergo an initial decline of 2 to 5% in the first years, but it is our work to manage the health of batteries for the rest of the life of the vehicle,” adds Cordova Tineo.

One of the factors that can lead to a “sudden death” in a battery – or the point where its performance decreases quickly below what is deemed normal – is consistent at extreme rates, which, according to Cordova, can cause lithium veneer and a massive reduction in battery performance.

“This is why we use the waterproof load, where the power supply is gradually accelerated when the battery reaches the optimal load state, narrowing when it reaches the brand 70 or 80%, then slowing down,” he explains.

Real world results

Although Porsche would not exclude new innovations in the load of electric vehicles, it does not hastily jump on the megawatt train at the moment.

Otmar Bitsche, principal consultant in the development of batteries and one of the oldest EV engineers in the company, says that the charges out of China are “good for public relations but not always practical in the real world”.

“The physics of all this is complex and it is even before we consider the infrastructure necessary to make it work,” he added.

During a real world demonstration in China, Inside EVS reported that Han L of Byd, which is the first to use its super electronic platform with the latest flash battery, would attract 767 kW of power until it reaches a 40%load state (SOC), maintained stable at 633 kW until it reaches 50%, then falling to 463 kW because it reached 60%.

Overall, the car won 262 miles in about five minutes. Impressive stuff.

But despite BYD’s statements that the battery battery does not affect the warranty, the technology was not long enough for us to know what state it will be in five or ten years, long after the guarantee.

In addition, most of these new generation ultra-fast Chinese packs use a chemical composition of lithium-ion phosphate (LFP), rather than the Nickel Manganese Cobalt (NMC) which is used by Porsche in its Taycan and Macan models.

Porsche is currently working to recover approximately 90% of the raw materials used in its NMC batteries in order to considerably reduce dependence on the farm.

Recycling of fast -charge LFP batteries, on the other hand, is widely considered as a more complicated task and has a lower profitability analysis due to the lower economic value of their content.

Driving dynamics count

The other key factor for Porsche is to conduct the dynamics, undoubtedly one of the most important pillars of the brand.

Even his daily electric SUV, the formidable Macan, is an absolute hoe to drive and will give many modern sports cars a race for their money on the race circuit.

Otmar Bitsche, main consultant in the development of batteries, says that there is a delicate balance to have with overall weight, energy density and load speeds, whose perfect concoction will go to the long -awaited electric sports cars.

The next 718 Boxster and Cayman should present the next generation of Porsche EV Motopropulsers, Bitsche saying that a range of around 370 miles on a single load would be “enough” for most sports cars.

The current architecture of 800 V of the company allows a maximum load speed of 270 kW, which is sufficient to store the largest Taycan battery pack from 5% to 80% in just 22.5 minutes.

Expect that the Boxster and Cayman have smaller packs and new integrated load technology, which in turn will see them even faster.

It is this notion of “to be sufficient” for most users that Bitsche reiterates when faced with the subject of megawatt load speeds, because it believes that the additional technology and equipment required to operate, not only on the part of the manufacturer, but charging networks, have potential negative effects on the way a vehicle and a vehicle and the results of the company.

An ultra-fast future

This week, the Society of Automotive Engineers in the United States has just published a new SAE J3400 / 2 standard which defines how a compatible North American charging port of 1,000 kW will look like technology.

However, as some criticisms have pointed out, even the Chinese demonstrations of the real world only put themselves at 1,000 kW during a seconds question during the charging sessions, before shrinking around a 600 -year stable kilowatts, then falling further.

Consequently, some Industry initiates believe that it would be more beneficial (and cheaper) to create a reliable network of chargers of 500 kW which can provide this type of speed for a greater proportion of the load session.

This would be equivalent to stops of 8 to 10 minutes for many, which is equivalent to the time spent in most service stations, according to a white paper.

Finally, and perhaps especially for a brand like Porsche, the load of megawatt is always a relative unknown, with few research available on the longevity of battery technology after many years or the reliability of it in extreme weather conditions.

“The increase in load efficiency and the reduction in charge times is one of our priorities,” said Dr. Matthias Goldsche, physicist and battery expert in Porsche.

“But this is not the only thing, because we think that the next generation of cars can reach an ideal point of an acceptable daily range for the majority of our customers, fast load speeds, driving dynamics and the ability to create durable, reliable and recyclable batteries,” he adds.