- 3D printers have built complex concrete parts faster, but long -term sustainability remains largely not tested

- OAK RIDGE completed reactor shielding in a few days, increasing speed debates to industry in industry

- Advanced construction methods are based more on software, reducing the workforce while increasing system dependence

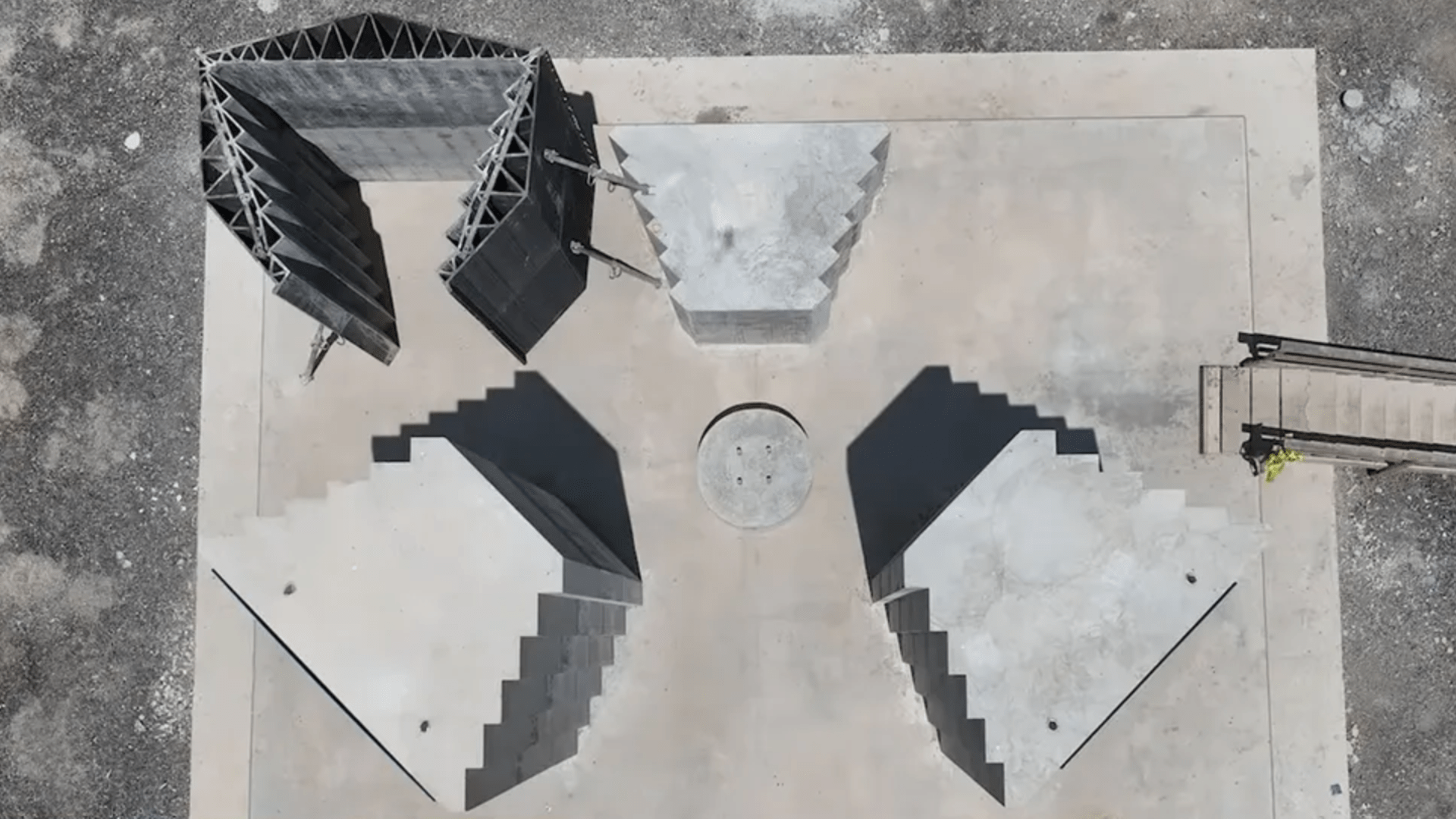

In the east of Tennessee, a 3D printer arm was used to build concrete shielding columns for a nuclear reactor.

The work is part of the project as a low -power demonstration reactor, supported by the American energy department, and marks a new direction in the way nuclear infrastructure is built, with 3D and AI printing tools playing major roles.

And according to Oak Ridge National Laboratory (Ornl), large parts of the construction were completed in just 14 days, which could have taken several weeks using conventional methods.

Efficiency gains clash with the prudence of engineering

The new method uses 3D printers to create detailed mold for concrete casting, even in complex forms, in order to make construction faster, cheaper and more flexible while relying more on materials and labor in the United States.

AI tools have also played a role in the project, because Ornl used technology to guide parts of the design and construction process.

These tools can help reduce human errors and accelerate work, especially when creating difficult or unique documents, but in great function of AI also raises questions. How can manufacturers ensure that these systems will not make mistakes unnoticed? Who checks automated decisions?

The project is also a response to the increase in energy requests – because AI systems and data centers use more power, nuclear energy is considered a stable source to support them.

Some experts say that future AI tools could eventually operate on energy from reactors they have helped to design, a feedback loop that could be both efficient and risky.

The use of 3D printing in this project makes it possible to build precise structures more quickly.

However, it is not yet clear how these 3D printed parts will hold over time.

Nuclear reactors must last decades and failure in any part of the structure could be dangerous. Test and quality tests must follow the speed of new construction methods.

For the moment, 3D printing and AI seem to offer powerful tools for the nuclear industry.

But although faster construction is a major advantage, security must remain the main concern – this “new era” can make improvements, but it will need close attention and caution at each stage.

Via Toms equipment