- Lighter, more powerful and more affordable in-wheel motors are on the horizon

- Elaphe Propulsion Technologies revealed a 2,000 hp supercar concept

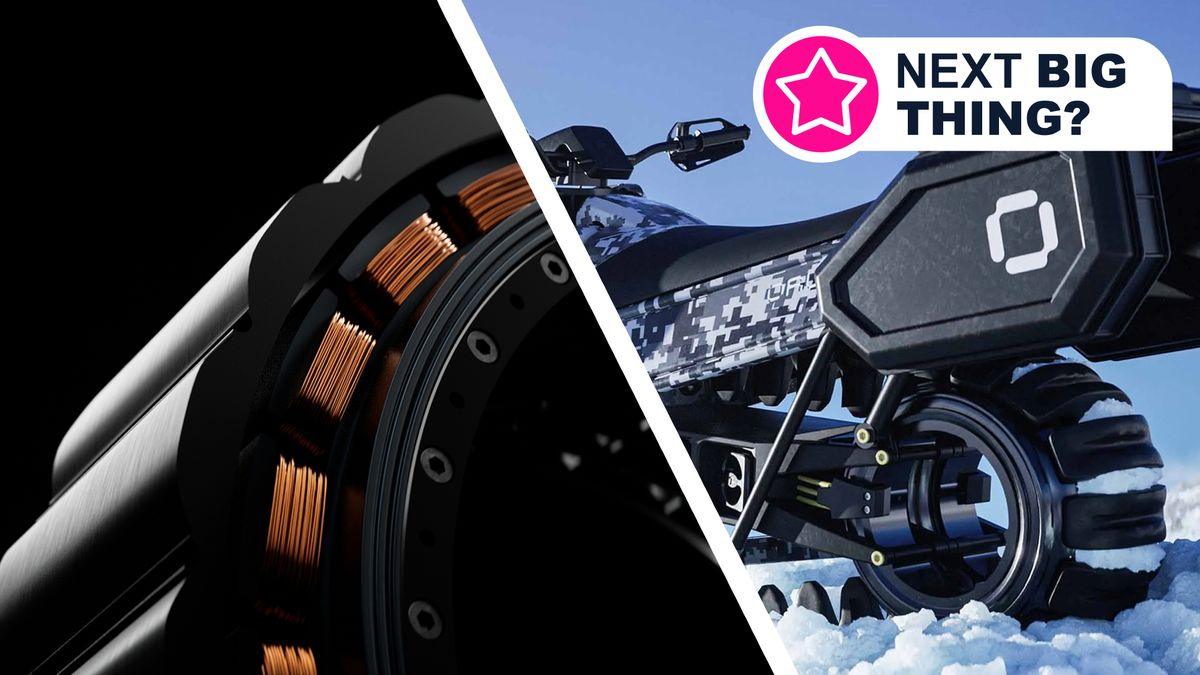

- Donut Lab claims its motors can power a range of products

Most modern electric vehicles use an electric motor that drives either the front axle or the rear axle – or both, if it has all-wheel drive and two motors. This works perfectly, but it is not the most efficient solution, as energy (and therefore battery life) is lost to mechanical friction via the transmission, driveshafts, etc.

Additionally, automotive designers and engineers are relatively limited in how they can package new vehicles because they must take care of the plumbing required for a bulky electric drivetrain.

The next big thing in electric vehicles is the introduction of in-wheel motor (IWM) technology, which has been around for decades but has taken a long time to be perfected to a point where it can be introduced affordably and realistically in production cars.

Donut Lab, a subsidiary of Verge Motorcycles – the futuristic electric motorcycle brand that pioneered in-wheel motor technology for high-performance two-wheeled transportation – showcased the latest generation of its technology at this year’s CES 2025 , and it has the potential to change the game again.

In-wheel motor technology has been considered too expensive, underpowered, and too bulky for mass-produced cars, as a huge amount of weight is essentially positioned in one area (the wheels) that needs to be as as light as possible – a concept dubbed “unsprung mass” by automotive experts, which refers to anything not supported by the vehicle’s suspension system.

It plays a central role in a vehicle’s handling, but Donut Lab claims its latest engine technology can weigh as little as 40kg, while delivering a power-to-weight ratio that far exceeds anything currently on the market. walk. Unsprung mass becomes a moot point.

The company’s CEO Marko Lehtimäki claims that an automotive-spec 21-inch version can deliver a mind-boggling 630 kW, or 845 hp. Multiply that number by four, and the next generation of supercars could easily produce 3,380 horsepower, if manufacturers can figure out how to transfer that power to the road.

Silly supercar daydreams aside, the technology will more likely be used in a more restrained manner, with a few lightweight, less powerful integrated motors powering the rearmost wheels, which could still produce a dizzying 600-800 hp, without the associated costs.

There’s a 17-inch application for motorcycles, which makes around 200 hp (it’s up there with most modern superbikes) and weighs just 21 kg, while a 12-inch version weighs just 8 kg.

Lehtimäki says his company has managed to achieve top-notch performance with “a smaller amount of active materials”, meaning manufacturers can jump on the wheel motor bandwagon and save up to 50% on costs manufacturing compared to traditional electric vehicles. engines.

Analysis: the wheels are in motion

Donut Lab wasn’t the only in-wheel motor pioneer on display at CES this year, as Slovenian company Elaphe Propulsion Technologies also showed off its ultra-thin Sonic 1 hardware, capable of developing 268 hp, while still leaving plenty of space inside a 21 inch wheel. for standard high performance disc brakes.

This would make the engines suitable for use in high-performance driving situations, such as on racing circuits, where reliable and predictable stopping power is essential.

The company showcased its technology in the Italdesign Quintessenza concept, which takes the form of a futuristic electric pickup/SUV hybrid featuring a Sonic 1 motor in each wheel developing more than 2,000 hp.

Elaphe says it is working on mass production concepts that it hopes to be able to develop alongside equipment manufacturers. However, don’t expect to see a production version until 2030 or later.

Despite these long lead times, the race is on to be first to introduce in-wheel motors to the buying public. BMW announced last year that it was working with Munich-based electric motor engineers DeepDrive to develop in-wheel motor technology that could be scaled up to such an extent that it would be financially profitable for electric vehicles mass produced.

Likewise, serial innovator Hyundai Motor Group has been working and refining its “Uni Wheel” technology since 2023.

There has been no update on recent progress, but the Korean company said the technology could completely change the way it packages electric vehicles in the future, helping it improve vehicle range. batteries and considerably increase the durability of its engines.