- Anker Eufymake E1 prints textures up to 5 mm thick using UV curable ink, no filaments

- More than $ 45 million collected on Kickstarter make E1 the most financed project to date

- EUFYMAKE E1 supports more than 300 materials, including metal, leather and curved surfaces

Anker’s latest incursion in creative tools has storming Kickstarter unexpectedly with its new aircraft, the EuFymake E1, generating nearly $ 45 million in his campaign, making it the most funded Kickstarter project to date.

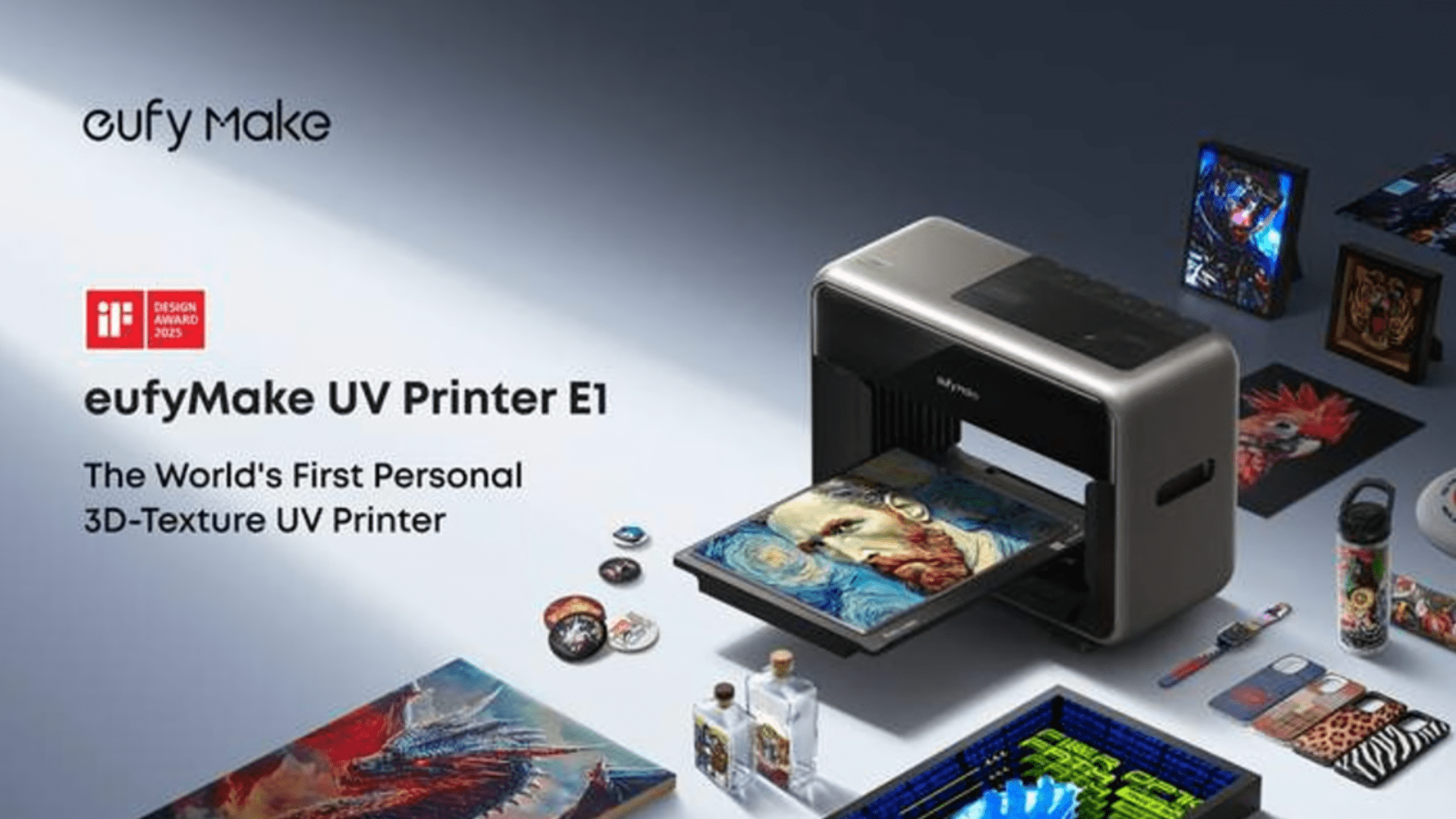

Developed under the EUFY sub-brand of Anker, the E1 is marketed as the first UV printer with personal 3D texture in the world.

Although excitement among donors is undeniable, the real question is whether this 3D all-in-one printer machine can be up to its extraordinary promise.

A different version of 3D printing at home

Unlike a typical domestic 3D printer, the EUFYMAKE E1 does not work with filament to build objects – it rather uses ink and an anker process calls for AMASS3D technology to superimpose the ink in textured conceptions on flat or curved surfaces.

The textures can reach up to 5 mm thick and can be printed on more than 300 materials, including glass, leather, metal and wood.

It also supports cylindrical objects by rotating printing and direct release to the film to make personalized stickers.

From a technical point of view, the E1 is full of features, including laser levels, an 8 MP camera with IA positioning and the Colormaestro system which offers lively and durable color prints.

The company also promises a practical user experience, thanks to the Jetclean autonomy system.

These extras could appeal to amateurs and small businesses, in particular those that produced personalized goods such as ornaments, goblets or vinyl stickers.

However, it is not only an intelligent manufacturing tool; It is clearly positioned as a major argument for the DIY market.

With the EUFYMAKE E1 aimed at consumer space, questions arise on long -term sustainability, ink costs and the precision of the real world, the factors that often separate a gadget from a reliable tool.

Low -operating cost allegations, such as “a dollar of ink on a personalized metal panel”, may seem convincing, but they will have to be tested outside of promotional videos.

Ink consumption is a significant consideration for 3D printers. Although the EUFYMAKE E1 campaign claims that 600 ml gives around 1,000 small impressions, there are no detailed ML-PAR data for the 3D output.

Since an ink set would cost around $ 299, this means that an average user could spend about $ 0.50 per print, and perhaps more depending on the application – and in the long term, this could be too expensive for small businesses.

Users looking for the best printer for daily use or even the best laser engraver for material customization may need to compare themselves carefully before committing.